Optimizing Efficiency & Reliability in Hydrogen Electrolysis

Green hydrogen is a cornerstone of the global shift toward net-zero emissions. Produced via water electrolysis powered by renewable energy, it offers a sustainable alternative to fossil fuels. However, achieving cost-effective and efficient hydrogen production while maintaining the long-term durability of electrolyzers remains a challenge.

Central to this process is the performance of the electrolyzer, a sophisticated system responsible for splitting water into hydrogen and oxygen through multiple interconnected cells operating under high electrical loads. The performance of each cell directly impacts the effectiveness of the entire system. Over time, factors such as membrane degradation, catalyst degradation, contamination, and fluctuating conditions can lead to efficiency losses, unplanned downtime, and ultimately, reduced system life.

The Role of Single Cell Voltage Monitoring

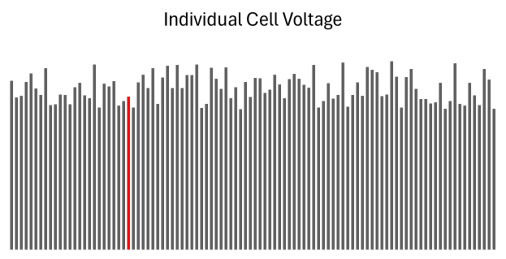

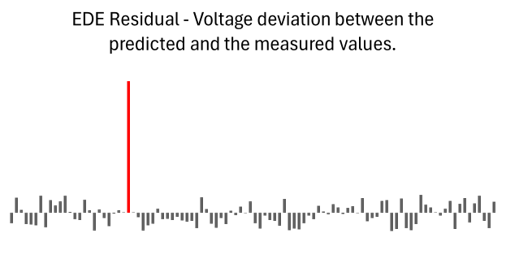

Single Cell Voltage Monitoring addresses these challenges by enabling real-time monitoring of individual cell performance within the electrolyzer stack. Unlike traditional methods that measure the stack’s overall efficiency, cell voltage monitoring identifies variations in cell voltage to provide insights into the health of each cell. This allows operators to detect inefficiencies and take corrective action early, reducing energy waste, enhancing operational reliability, and extending system life.

This is where R2’s Single Cell Voltage Monitoring comes into play, empowering operators to detect subtle changes that indicate potential problems early and take action to ensure optimal performance and avoid energy losses, reduced hydrogen output, and increased maintenance needs.

Enhancing Electrolyzer Efficiency through Real-Time Monitoring

With cell voltage monitoring, operators can continuously monitor voltage levels of each cell within the stack and adjust the system as needed to ensure optimal operation, even during periods of dynamic energy input. This leads to reduced energy consumption, minimized operational downtime, and a more efficient hydrogen production process. The real-time data also enables more precise control over the entire system, reducing the likelihood of energy losses or system imbalances.

Ensuring Long-Term Reliability

As the demand for green hydrogen grows, electrolyzers must deliver reliable performance over extended periods. A single cell failure can disrupt the entire operation, leading to costly outages. R2’s single cell voltage monitoring system plays a crucial role in ensuring that these systems operate within safe parameters and avoid safety risks, such as increased risk of overheating and formation of potentially explosive gas mixtures (e.g. hydrogen and oxygen). Early detection of anomalies prevents issues like cell overvoltage or underperformance which can lead to early system degradation.

The ability to track voltage trends of each cell over time and the data-driven insights generated, not only prevents damage, but also provides valuable data for ongoing optimization. This feedback loop allows for continuous improvement in system design and performance, ensuring that electrolyzers remain reliable, efficient, and ready to meet the future demands of hydrogen production.

These capabilities are essential for advancing the adoption of hydrogen as a clean energy source across various sectors.

R2: Leading the Charge in Hydrogen Innovation

R2 has long been committed to pushing the boundaries of industrial innovation, and its work in hydrogen production is no exception. Our solutions are designed to help operators maximize efficiency, minimize downtime, and ensure the long-term reliability of their systems. As the hydrogen economy grows, we believe that innovations in monitoring and maintenance will be key to ensuring a sustainable and scalable future.

By implementing Single Cell Voltage Monitoring systems, operators gain the tools to produce hydrogen efficiently, paving the way for a greener and more economically viable energy future.