TURNING DATA INTO INFORMED DECISIONS

Things are not always as they appear, one slowly escalating parameter may not be problematic but combined with other factors, could lead to an incident. With EMOS® Advisory System, all plant parameters and relationships are monitored, covering all possible phases of electrolyser operation: from start-up/ filling, to operating at full load, and back to shutdown / draining.

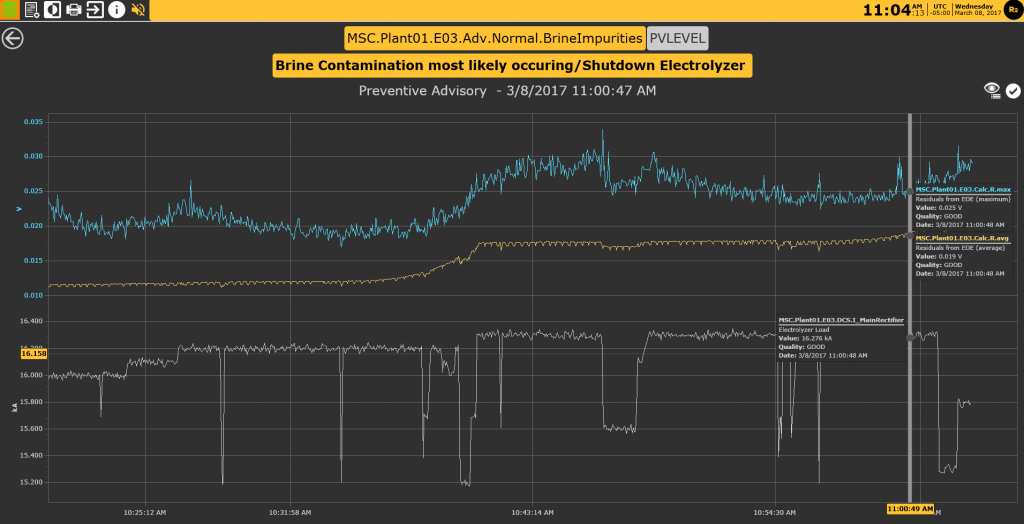

If a situation occurs that could lead to an incident, operators are advised which action(s) to perform in order to reduce or eliminate the threat.

Key Features and Benefits

benefits

features

Fewer Unplanned Shutdowns

Actionable Insights to Prevent and Fix Cell Room Incidents

Shorter Downtime when Resolving Incidents

Root Cause Identification of Each Fault

Improved Operator Effectiveness and Efficiency

66 Detectable Hazard Types (Advisory AI)

Increased Throughput

Recommended Corrective Action for Each Incident

Reduced Training Time

Developed for the Chlor-Alkali, Chlorate, and Hydrogen Industries

Fewer Incidents Escalated to Shift Supervisors/Engineers

Covers All Operation Modes (Startup, Normal, Shutdown, etc.)

Advisory AI: Early Detection of Faults

EMOS® Advisory is offered in two product tiers: Advisory and Advisory AI. Leveraging machine learning, Advisory AI can detect faults hours before they occur by comparing, in real-time, the actual cell voltage with the predicted voltage, for the specific process conditions. Any important discrepancy between the two prompts an Advisory alarm, which enables operators to plan their intervention before an emergency shutdown is set off. This early detection of faults is unmatched in the industry!

Features

Advisory

Advisory AI

Number of Faults Detected

41

66

Early Detection of Some Faults, Hours Before they Occur

✔

EMOS® Voltage Measuring Hardware

Not Required

Required

Documentation

EMOS® Advisory AI protects electrolysis plants against many faults such as brine impurities or insufficient electrolyte flow to an individual cell, which are impossible to uncover using other vendor equipment. Based on its unique experience of analyzing over 100 000 electrolyser cells worldwide, R2 has developed best-in-class proprietary algorithms that increases plant safety and decreases the number of unplanned shutdowns.

Download:

EMOS® Advisory Datasheet (English)