automatic start-up and shutdown detection

One of the worst things that can happen in a cellroom is the mixing of hydrogen and chlorine gas through a perforated membrane. Damaged membranes significantly increase the risk of an explosion. Pinholes can also allow caustic soda to pass from the cathodic compartment into the anodic compartment, damaging the anodes and possibly causing outside leakages. Pinholes will always reduce the current efficiency of a cell as caustic soda is lost and forms unwanted by-products with the chlorine (e.g. chlorates, hypochlorites). Avoid safety hazards and serious equipment damage by detecting defective membranes as early as possible.

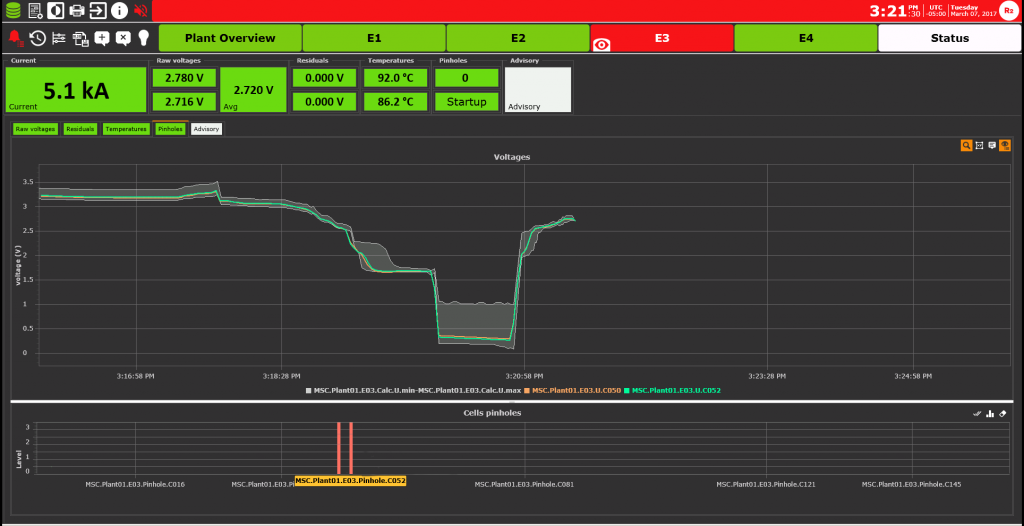

The EMOS® Pinhole Detector, during a start-up or following a shutdown, automatically detects membrane pinholes, analyzes their severity (from “Pinhole Level 0: No Membrane Pinholes” to “Pinhole Level 3: Severe Membrane Pinholes, Safety Issue”), and notifies the operator. These 4 severity levels provide more specific, actionable information when compared to other pinhole detection methods which typically do not feature severity levels.

Since membranes with pinholes are identified early on, you can then track and follow-up on them to minimize coating degradation and production losses. This also allows you to efficiently manage membrane replacement during planned shutdowns and avoid delays during plant start-ups. In addition, the EMOS® Pinhole Detector increases plant safety by helping you to avoid operating with weakened or damaged components.

Key Features and Benefits

benefits

features

Increased Safety

Automatic Detection of Membrane Pinholes During Startup and Shutdown

Increased Maintenance Planning Efficiency

Classification of Pinhole Severities

Extended Component Lifetimes

Track the Evolution of Pinholes

No More Time-Consuming Bubble Tests

Detection Results Displayed in the Monitoring Software

Documentation

One of the worst things that can happen in the cell room is the mixing of hydrogen and chlorine gas; the membrane acts as a barrier and prevents this from happening. If there is damage to the membrane, this brings a real risk of an explosion. An unnoticed pinhole can be a serious hazard, which must be prevented.

Olin Chlor Alkali Products and Vinyls is the leading chlor-alkali producer by capacity globally. Over time, Olin, like all chlor-alkali producers, face the issue that cell membranes develop pinholes, or small tears, due to several conditions ranging from age, pressure swings inside the cells, or abrasion. Pinholes can cause lower efficiency of the cells. According to Olin, “Our challenge is to detect these pinholes in their early stages, allowing an opportunity to repair or replace the membranes.”

This case study discusses how Olin uses EMOS® Pinhole Detector to reduce the risk of membrane damage.

Download:

Case Study on Preventing Membrane Pinholes (English)