Power Efficiency & Stack Performance for Green Hydrogen

Tailored to address water electrolyzer standards, our EMOS® SIL2 Safety System ensures hydrogen production is both efficient and secure. In addition to rigorous performance analyses, detection of numerous faults, and recommendations to enhance overall productivity, R2’s multi-layer protection algorithms and comprehensive diagnostics easily integrate to offer fail-safe and independent operation. This ensures a reduction in downtime and more efficient running of your plant.

In hydrogen electrolysis, monitoring voltages is vital for assessing process effectiveness and hydrogen production integrity.

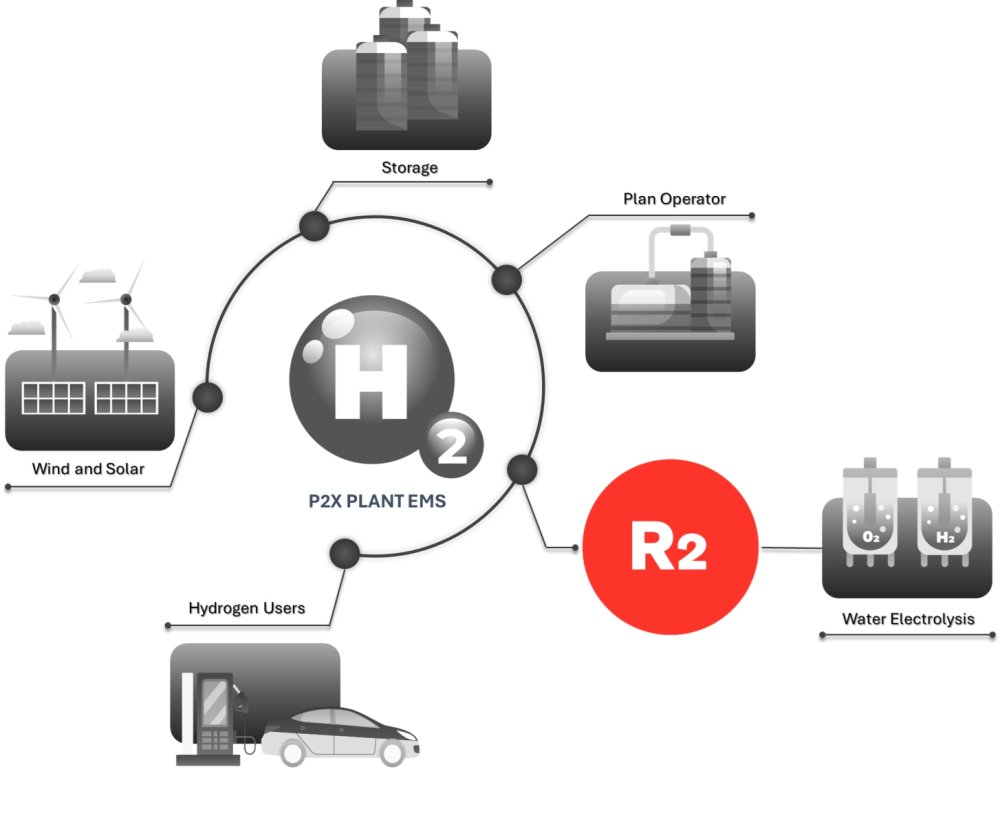

Our robust technology and software offering is the connection between your electrolyzer and the P2X Plant EMS ecosystem, enabling you to optimize the power consumption of your electrolyzer while handling the power fluctuations caused by energy supply variances.

Capable of detecting and mitigating risks like membrane degradation and electrical shorts, our AI-Powered Condition Monitoring analyzes cell behavior in real-time to prevent operational issues and manage frequent starts and stops, thereby preventing accelerated cell degradation.

The power savings enabled through individual cell monitoring not only allows for operational cost savings but provides a rich data source for electrolysis technology R&D teams to analyze performance metrics, identify new optimization strategies, and develop next-generation solutions.

Unlocking OPERATIONAL BENEFITS with R2’s Solutions

MINIMIZE POWER CONSUMPTION

Overworked cells become inefficient and can damage the electrolyzer. Keeping operations within a ‘safe’ zone, avoids premature aging and ensures optimal performance.

MONITOR MEMBRANE HEALTH

The membrane is crucial for ion transport and preventing undesirable crossover. Protecting it extends the electrolyzer’s life and reduces costs and environmental impact.

HAZARDOUS OPERATION PROTECTION

Maintaining stringent operational standards is crucial to prevent hazardous incidents. Leaks often result from cell failures due to degradation, aging, and mechanical stress.

DETECT DAMAGED PARTS

Damaged parts can lead to costly and dangerous hydrogen and oxygen loss. AI converts raw data into actionable intelligence, offering a comprehensive view of plant health.

AI-POWERED CONDITION MONITORING

Advanced system capable of detecting and mitigating risks, analyzing cell behavior in real-time, and managing frequent starts and stops.

ELECTROlyzer safety

The electrolyzer cell room safety system that helps prevent and protect against irreversible damage caused by all known events.